WHY DE-BLACK

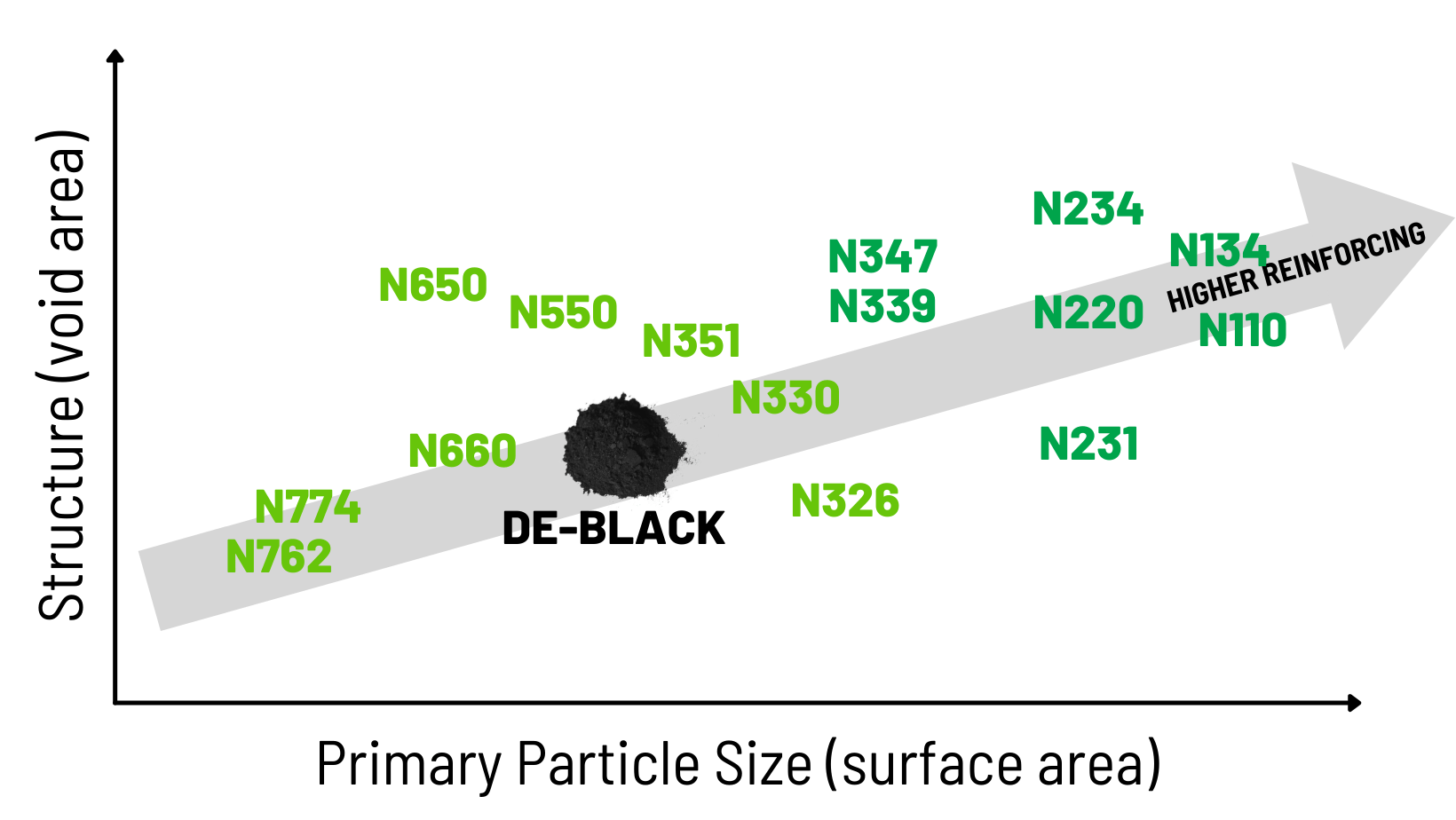

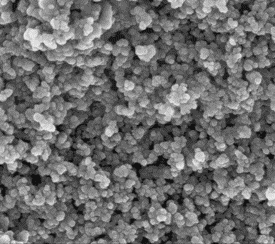

DE-Black is a medium reinforcing recovered carbon black made from end-of-life tire rubber. Delta Energy’s proprietary low temperature reaction process preserves key properties like surface area and dynamic void volume that enable DE-Black to replace or supplement traditional carbon blacks used in rubber products. DE-Black behaves similarly to traditional carbon blacks in both natural and synthetic rubber compounds.

DE-BLACK APPLICATIONS

Tire carcass, bead, side wall,

and tread

Rubber molding

and extrusion

Plastic molding

and extrusion

Tire carcass, bead, side wall,

and tread

Rubber molding

and extrusion

Plastic molding

and extrusion

Transforming the Tire Pyrolysis Industry

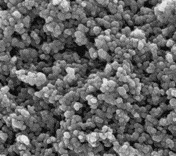

DE-Black outperforms typical pyrolysis char

DE-Black matches the structure of virgin carbon black

DEpolymerization™

- Unique, catalyzed, continuous, and hundreds of degrees lower than typical pyrolysis

- The process preserves surface area and structure of original carbon black

- DE-Black retains the original carbon black structure (Void Volume & Surface Area) that binds to polymer systems and helps promote compound physical properties.

- DE-Black reinforces rubber in the same way as certain virgin carbon black grades.

A SUPPLIER YOU CAN TRUST

- Qualified Supplier to Bridgestone Americas

- Qualified Supplier to Continental Tire and Conitech

LEARN MORE ABOUT OUR PRODUCTS

Contact us today to see how you can improve your business economics and sustainability with modern materials by Delta-Energy.

Contact Us

We will get back to you as soon as possible

Please try again later